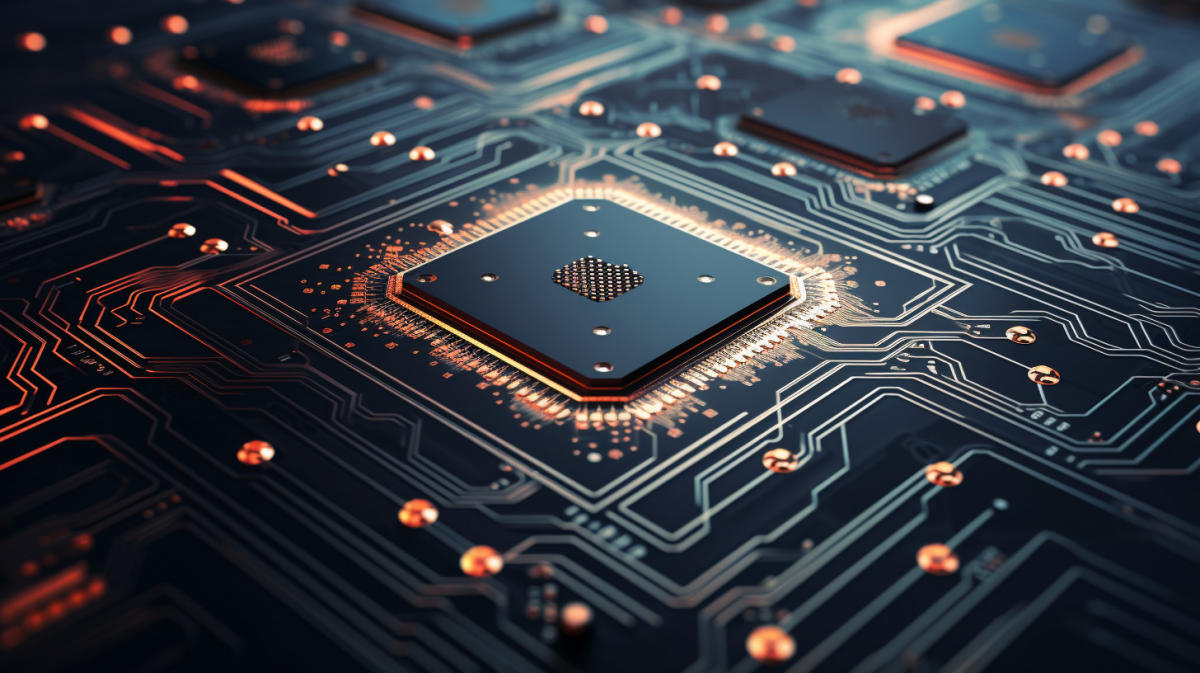

Chip Giant TSMC Floods Market: Cramer Reveals Surge in Semiconductor Orders

Jim Cramer's Market Insights: A Deep Dive into TSM and Top Stock Picks

In the fast-paced world of stock market analysis, Jim Cramer continues to be a prominent voice offering valuable insights. Recently, the renowned financial commentator shared his perspectives on a select group of stocks, with Taiwan Semiconductor Manufacturing Company (TSM) emerging as a particularly intriguing focal point.

During his latest appearance on CNBC's Squawk on the Street, Cramer provided a comprehensive overview of market trends and individual stock potential. Taiwan Semiconductor Manufacturing Company (NYSE:TSM) stood out among the discussed stocks, capturing the attention of investors and market watchers alike.

As a global leader in semiconductor manufacturing, TSM represents a critical player in the technology ecosystem. Cramer's analysis offers investors a nuanced perspective on the company's current market position and potential future performance.

Investors and market enthusiasts are advised to pay close attention to Cramer's insights, as his commentary often provides valuable context for understanding complex market dynamics and individual stock opportunities.