Factory of the Future: How AR and VR Are Revolutionizing Manufacturing's Bottom Line

The Manufacturing Revolution: How AR and VR Are Transforming Industrial Landscapes

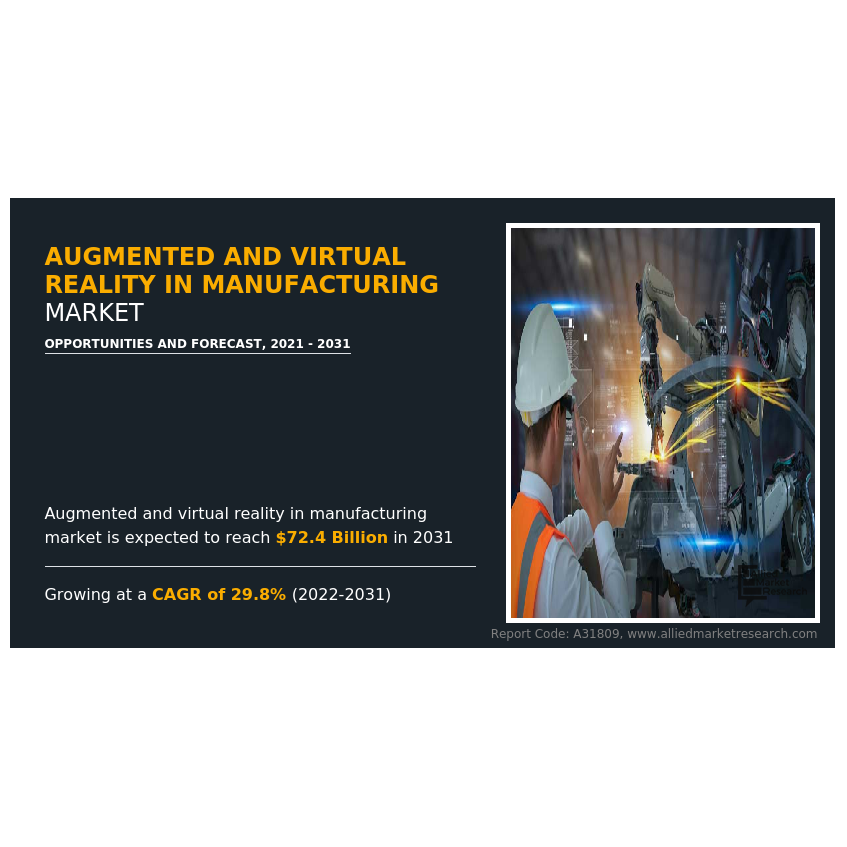

The global augmented reality (AR) and virtual reality (VR) manufacturing market is experiencing unprecedented growth, driven by strategic investments and compelling cost-efficiency benefits. As industries increasingly recognize the transformative potential of these immersive technologies, manufacturers are rapidly adopting AR and VR solutions to revolutionize their operational processes.

Cutting-edge investments are propelling AR and VR technologies from experimental concepts to practical, game-changing tools. Companies are discovering that these innovative solutions can dramatically enhance productivity, reduce training costs, and streamline complex manufacturing workflows. From virtual product design and prototype testing to immersive worker training and remote collaboration, AR and VR are reshaping how manufacturers approach innovation and efficiency.

The economic advantages are particularly compelling. By implementing AR and VR technologies, manufacturers can significantly reduce prototype development expenses, minimize human error, and accelerate time-to-market for new products. These technologies enable more precise visualization, real-time data integration, and enhanced decision-making capabilities across various stages of manufacturing.

As technological capabilities continue to expand and implementation costs decrease, the global AR and VR manufacturing market is poised for remarkable growth. Forward-thinking companies that embrace these transformative technologies are positioning themselves at the forefront of industrial innovation, gaining competitive advantages in an increasingly digital manufacturing landscape.