From Classroom to Factory Floor: Belleville Students Unlock Manufacturing Secrets

Precision and Determination: A Student's Remarkable Journey

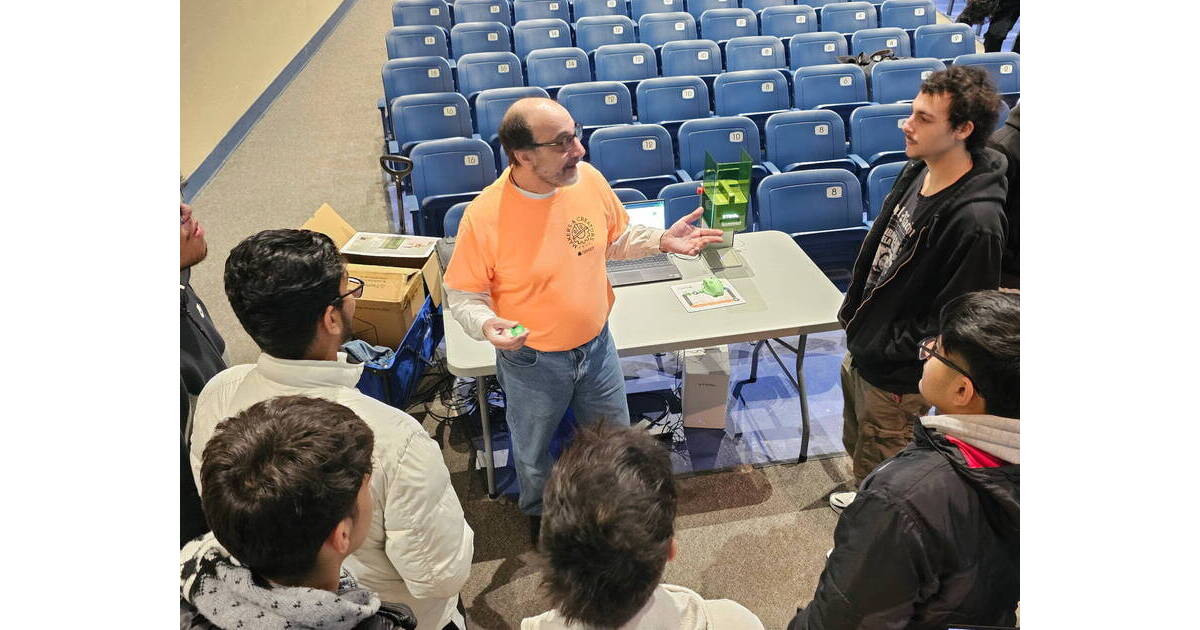

In the quiet halls of Belleville High School, Brian stood with unwavering focus, his body a testament to concentration and control. With his elbow precisely angled at 90 degrees and his head motionless, he began a deliberate horizontal movement that spoke volumes about his dedication and skill.

This was no ordinary moment for the senior—it was a culmination of countless hours of practice and perseverance. Each measured movement represented more than just a physical exercise; it was a reflection of Brian's commitment to mastering his craft.

As he continued his careful motion, onlookers could sense the intensity of his concentration, the subtle strength required to maintain such perfect form. This was more than just a routine—it was a performance of precision and discipline.