Robotic Revolution: Tech Giants Join Forces to Supercharge Industrial Production

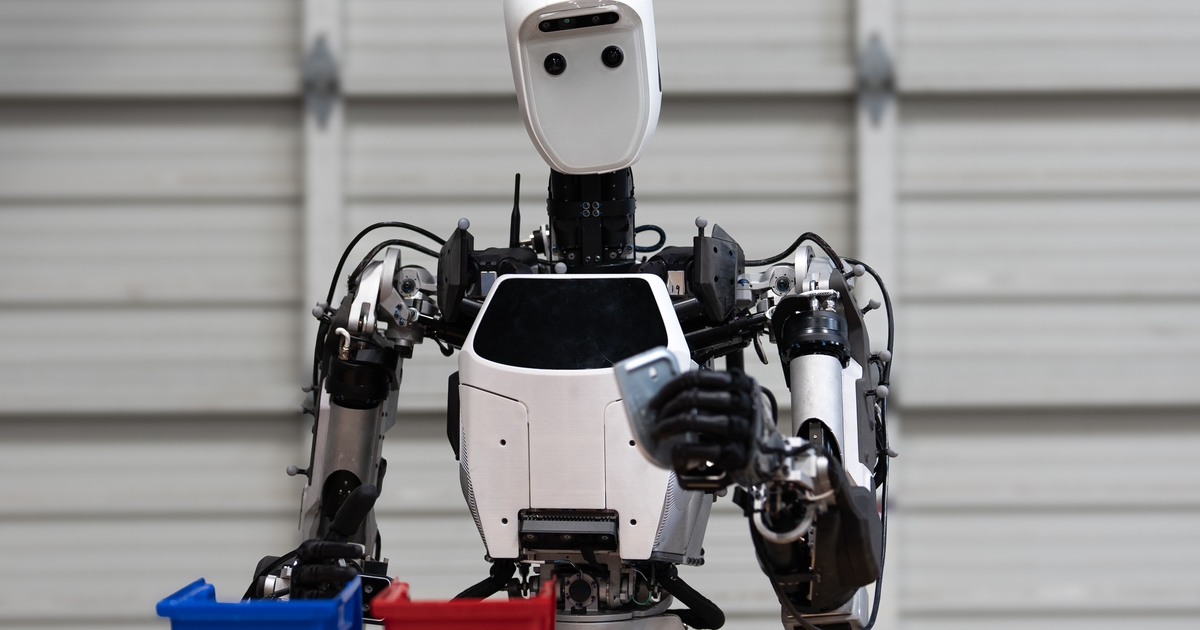

Apptronik and Jabil are pioneering a groundbreaking collaboration that promises to revolutionize manufacturing by introducing advanced humanoid robots into industrial operations. This strategic partnership aims to transform traditional manufacturing workflows by integrating cutting-edge robotic technology directly onto factory floors.

The collaboration leverages Apptronik's innovative humanoid robotics expertise with Jabil's extensive manufacturing infrastructure, creating a powerful synergy that could reshape how industrial tasks are performed. By deploying humanoid robots capable of complex, adaptable movements, the companies are setting a new standard for automation and workforce augmentation.

These sophisticated robots are designed to work seamlessly alongside human employees, handling repetitive, physically demanding tasks with precision and efficiency. The partnership represents a significant leap forward in industrial automation, demonstrating how advanced robotics can enhance productivity while maintaining workplace flexibility.

As manufacturing continues to evolve, this collaboration between Apptronik and Jabil signals a transformative approach to industrial operations, showcasing the potential of humanoid robotics to redefine workplace capabilities and performance.