Manufacturing Revolution: SAEKI Secures $6.7M to Reimagine Industrial Production

SAEKI: Transforming Digital Manufacturing Through Autonomous Innovation

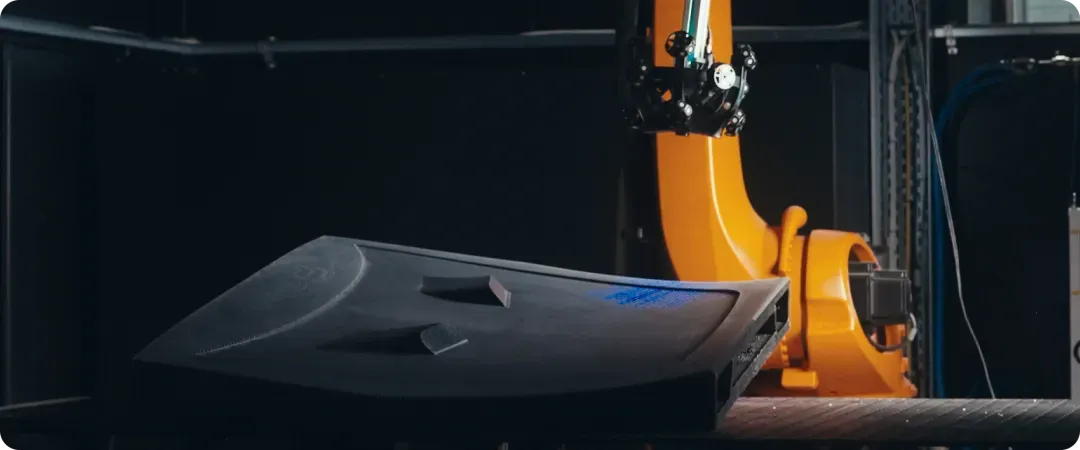

In the rapidly evolving landscape of industrial technology, SAEKI emerges as a groundbreaking force, seamlessly connecting the worlds of design and production through its revolutionary autonomous factory solutions. By leveraging cutting-edge artificial intelligence and advanced manufacturing technologies, SAEKI is redefining how companies conceptualize, design, and manufacture products.

At the heart of SAEKI's innovation is a sophisticated platform that eliminates traditional barriers between creative design and efficient production. Their autonomous factories represent more than just a technological advancement; they are a paradigm shift in manufacturing methodology. By integrating intelligent systems that can interpret complex design specifications and translate them directly into precise manufacturing instructions, SAEKI is dramatically reducing time-to-market and minimizing human error.

The company's approach goes beyond mere automation. SAEKI's intelligent systems learn and adapt, continuously optimizing production processes and creating a dynamic, responsive manufacturing ecosystem. This means manufacturers can now achieve unprecedented levels of precision, flexibility, and efficiency, all while maintaining the highest standards of quality.

As industries worldwide seek more agile and intelligent manufacturing solutions, SAEKI stands at the forefront of this technological revolution, promising a future where design and production are not just connected, but truly unified.