Inside Manufacturing: Cost-Cutting Strategies Fuel Ambitious Expansion Plans

Rulmeca Navigates Economic Challenges with Cautious Optimism in 2025

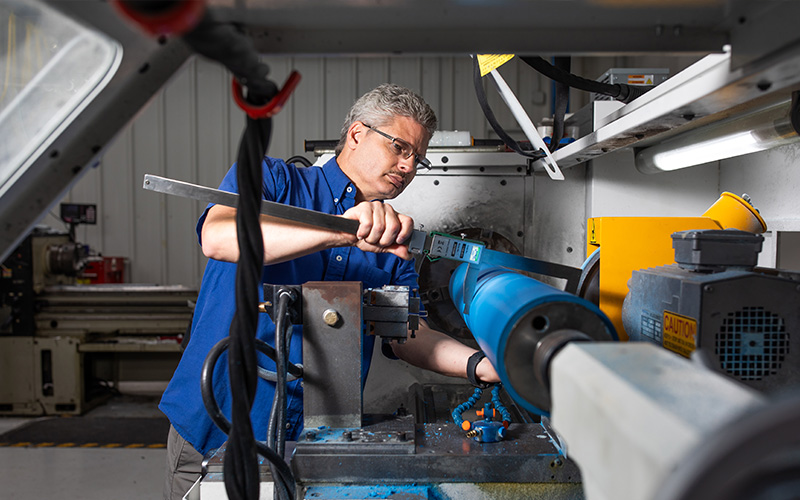

Nestled in Wilmington, Rulmeca, a motorized pulley manufacturer, is charting a strategic course through potential economic headwinds as it enters 2025. What began as a modest two-person operation in a shipping container back in 2003 has blossomed into a robust 14-employee enterprise occupying a spacious 30,000-square-foot facility.

Company President Brian Vrablic is keenly aware of the complex economic landscape ahead. "We're facing several critical challenges that could impact manufacturing," he explains. "High interest rates are currently dampening equipment purchases, and companies are carefully evaluating capital costs."

Key Economic Challenges

- Potential reduction in infrastructure spending as the federal infrastructure bill approaches expiration in 2026

- Sunsetting tax cuts from 2017 that could decrease personal and business spending

- Ongoing economic uncertainties surrounding interest rates and inflation

Fortunately, some potential disruptions have been averted. A potential ports strike was prevented when the International Longshoremen's Association and United States Maritime Alliance reached a tentative agreement, providing relief for manufacturers dependent on East Coast shipping routes.

Looking Forward with Optimism

Despite these challenges, Vrablic remains fundamentally optimistic. "Longer-term indicators are promising," he notes. "We anticipate interest rates will continue to fall, and labor rates are stabilizing, which will enable manufacturers to invest more confidently in both human and machine resources."

Rulmeca's leadership is committed to navigating these economic complexities, viewing 2025 as a year of strategic growth and adaptation. "We're excited to see how the year unfolds," Vrablic adds, reflecting a balanced approach of cautious preparation and entrepreneurial spirit.

As regional economists continue to monitor national economic trends, Rulmeca stands as a testament to resilience and strategic planning in the manufacturing sector.