Green Tech Giant ABB Backs Innovative Circular Manufacturing Startup Molg in Virginia Breakthrough

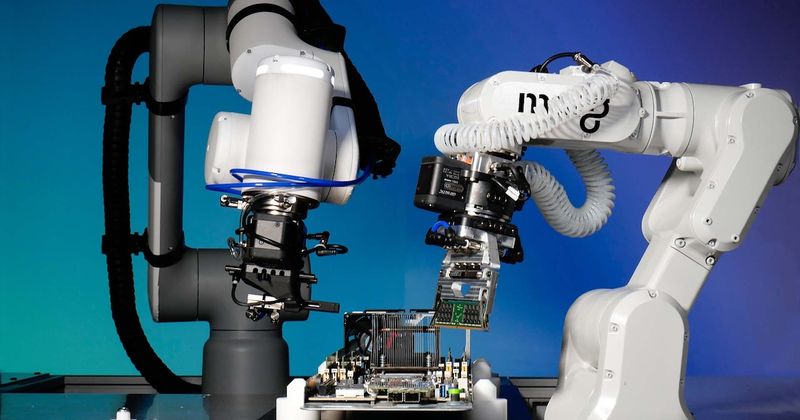

ABB Motion's Drive Products division is taking a significant step towards sustainable manufacturing by strategically investing in Molg, an innovative circular manufacturing company based in Virginia. This forward-thinking partnership aims to revolutionize the design and reusability of ABB drives, demonstrating the company's commitment to creating more environmentally conscious and efficient industrial solutions.

By collaborating with Molg, ABB Motion is positioning itself at the forefront of circular economy principles, focusing on optimizing product design to enhance recyclability and reduce waste. The investment signals a progressive approach to manufacturing that prioritizes sustainability without compromising technological performance.

The partnership is expected to drive meaningful improvements in how industrial drives are conceptualized, produced, and ultimately recycled, potentially setting new industry standards for circular manufacturing practices.