Global Electronics Manufacturing Services Set to Skyrocket: $188 Billion Boom Powered by AI and Emerging Market Dynamics

AI Revolutionizes Electronics Manufacturing: Market Poised for Significant Growth

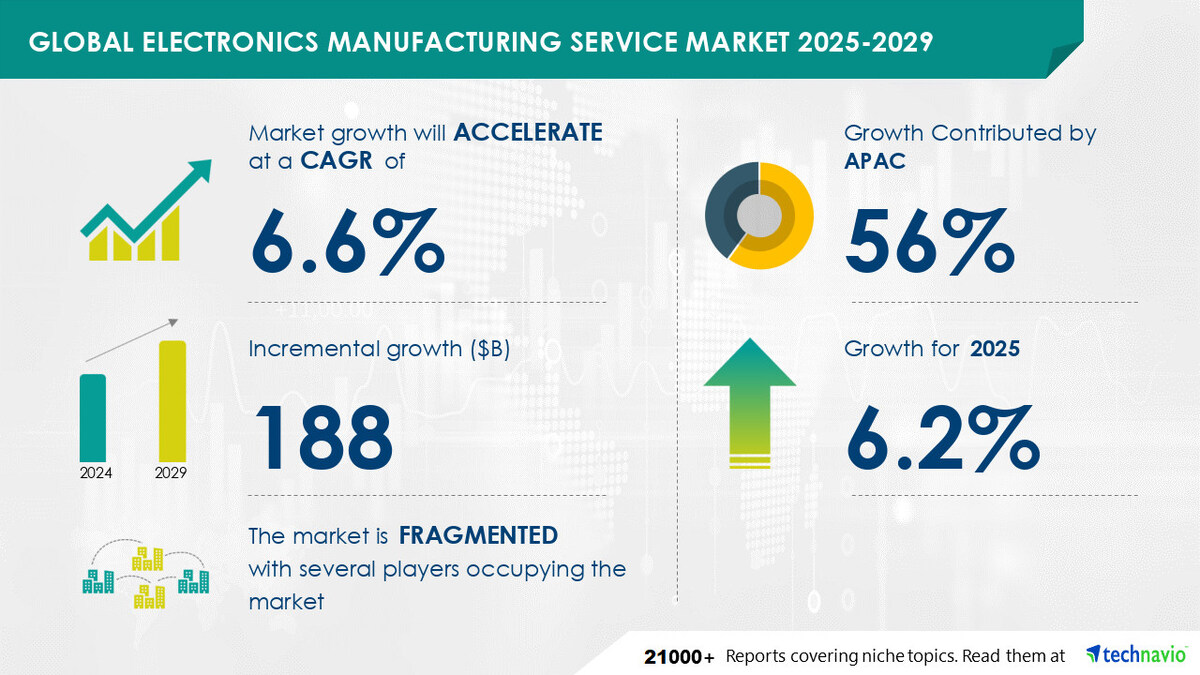

The global electronics manufacturing services (EMS) industry is experiencing a transformative wave, driven by the rapid integration of artificial intelligence technologies. Recent market research indicates a projected expansion of approximately $188 billion, highlighting the sector's tremendous potential and technological evolution.

Key Drivers of Market Transformation

- Advanced AI algorithms enhancing production efficiency

- Intelligent automation reducing manufacturing costs

- Predictive maintenance and quality control innovations

- Smart supply chain management solutions

Industry experts predict that AI will not just incrementally improve manufacturing processes, but fundamentally reshape how electronics are designed, produced, and distributed. The convergence of machine learning, robotics, and data analytics is creating unprecedented opportunities for manufacturers to optimize their operations and deliver cutting-edge products.

Future Outlook

As technology continues to advance, electronics manufacturing services are positioned to become more agile, precise, and responsive to market demands. The integration of AI represents a critical strategic imperative for companies seeking to maintain competitive advantage in an increasingly complex global marketplace.