Breaking: AI Revolution Transforms Factory Floors, Shatters Old Tech Barriers

AI is Revolutionizing Manufacturing Execution Systems: A New Era of Industrial Innovation

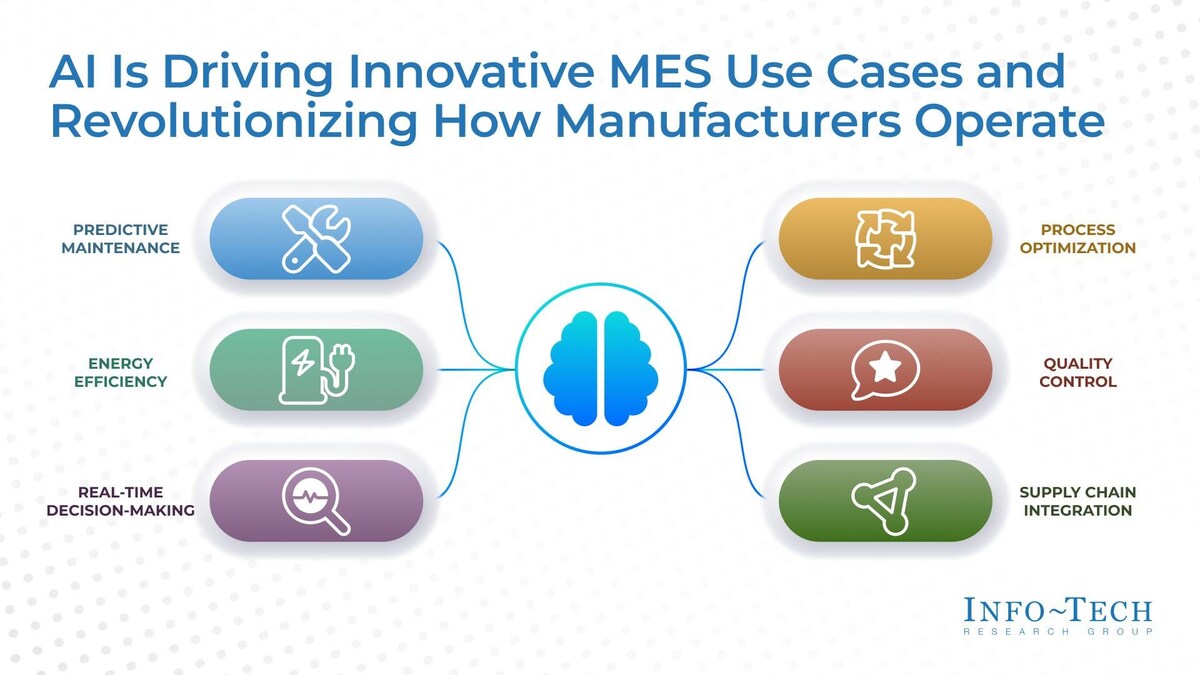

The manufacturing landscape is undergoing a transformative shift as artificial intelligence (AI) reshapes the core of manufacturing execution systems (MES). Recent research from Info-Tech Research Group unveils groundbreaking insights into how AI is driving unprecedented efficiency, productivity, and strategic decision-making in industrial environments.

At the forefront of this technological revolution, AI is not just enhancing traditional manufacturing processes—it's completely reimagining them. By integrating advanced machine learning algorithms and intelligent data analytics, manufacturers can now unlock capabilities that were once considered impossible.

Key advantages of AI-powered MES include:

• Real-time predictive maintenance

• Enhanced operational efficiency

• Dynamic production optimization

• Intelligent quality control

• Reduced downtime and operational costs

As industries increasingly embrace digital transformation, AI-driven manufacturing execution systems are becoming a critical competitive advantage. Companies that leverage these intelligent technologies are positioning themselves at the cutting edge of industrial innovation, ready to meet the complex challenges of modern manufacturing.

The future of manufacturing is here, and it's powered by artificial intelligence.