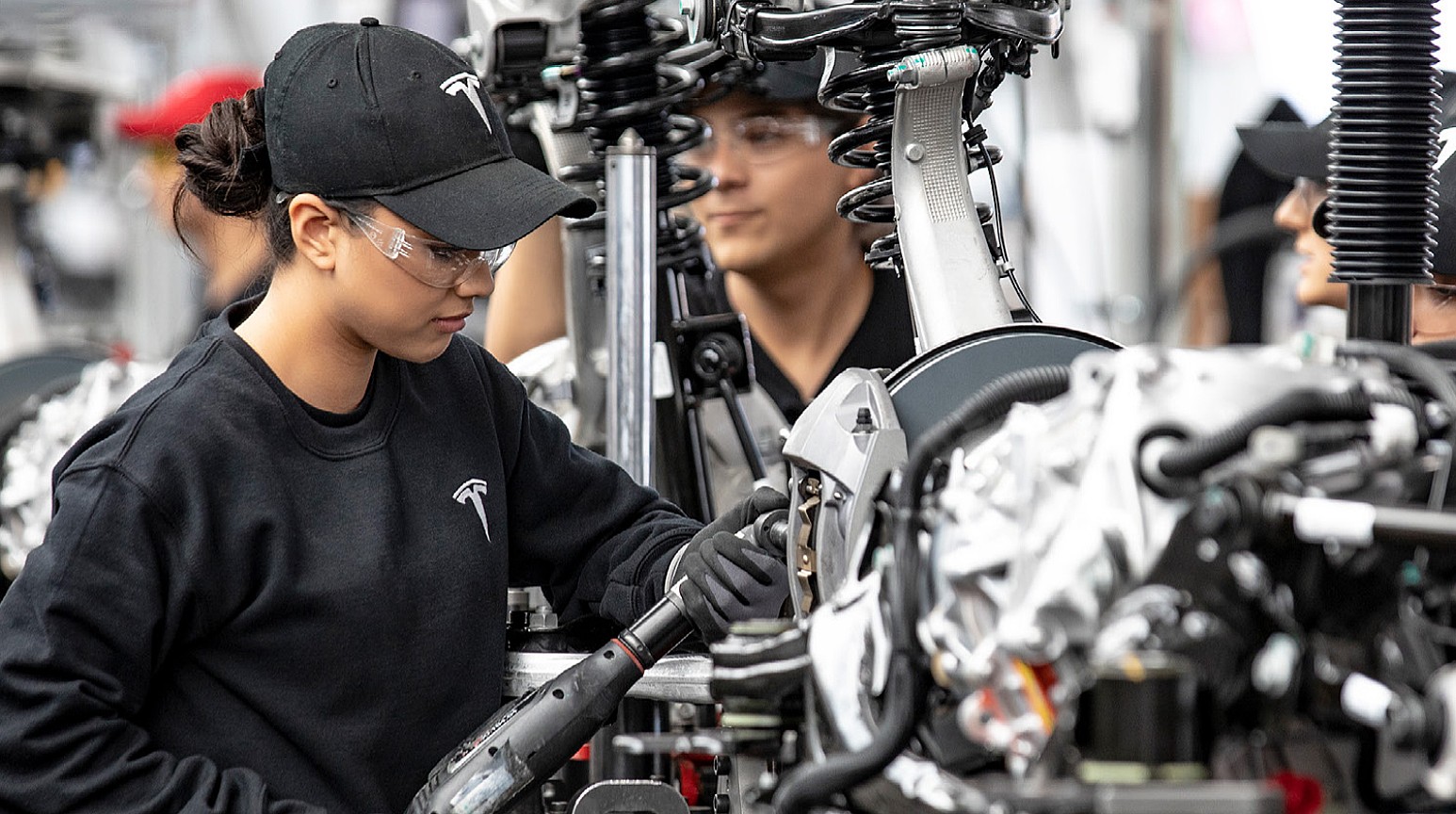

Tesla's Electric Revolution: Breaking the Curse of U.S. Industrial Decline

Tesla Poised to Lead American Manufacturing Renaissance, Morgan Stanley Predicts Morgan Stanley analysts believe Tesla stands at the forefront of a transformative opportunity in the resurgence of domestic manufacturing. The electric vehicle pioneer could play a pivotal role in reshaping America's industrial landscape, leveraging its innovative technology and strategic vision. As companies increasingly seek to bring production back to U.S. soil, Tesla is uniquely positioned to capitalize on this trend. The company's advanced manufacturing capabilities, commitment to technological innovation, and existing infrastructure make it a potential game-changer in the national manufacturing revival. The investment firm's insights suggest that Tesla's ability to integrate cutting-edge technology with domestic production could not only boost the company's growth but also contribute significantly to the broader economic revitalization of American manufacturing. With its advanced electric vehicle platforms and sustainable energy solutions, Tesla represents more than just an automotive company – it embodies the future of American industrial innovation. Investors and industry watchers are closely monitoring Tesla's potential to drive this manufacturing renaissance, recognizing the company's unique capacity to blend technological prowess with domestic production strategies.