Cellular Precision: The Molecular Machine That Prevents mRNA Manufacturing Mistakes

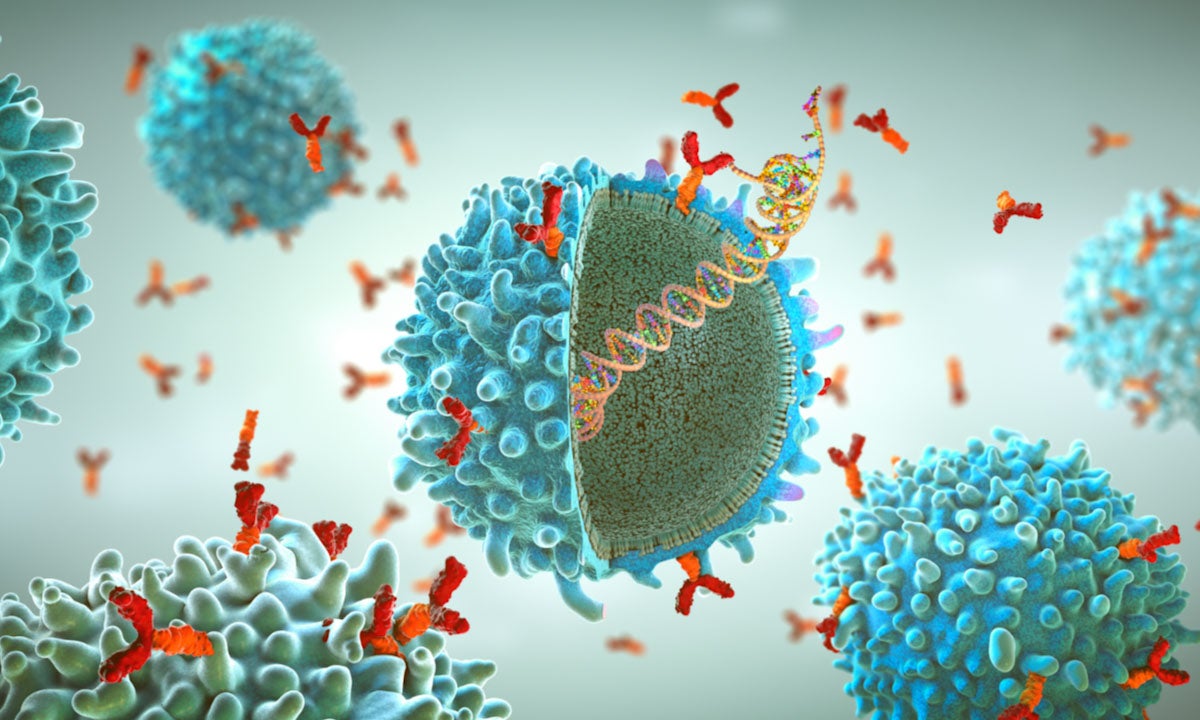

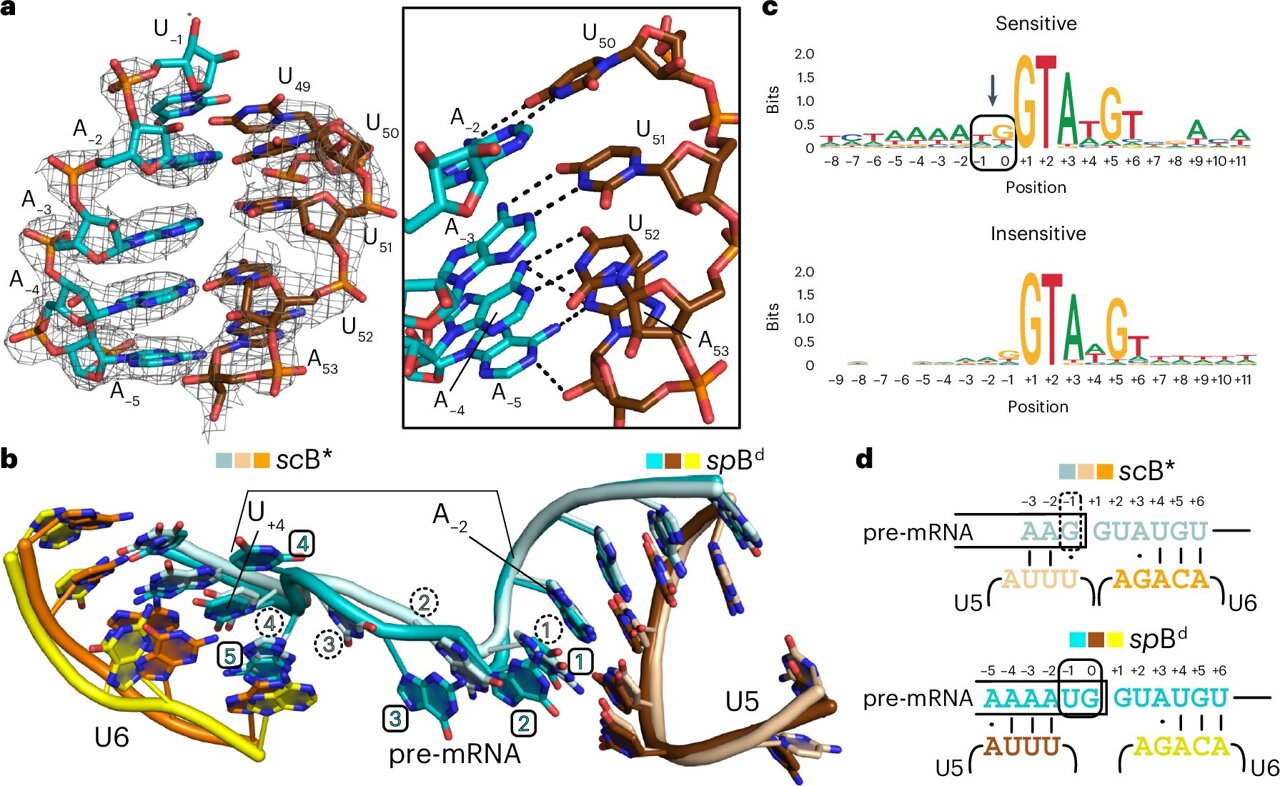

Inside every cell, a remarkable molecular marvel works tirelessly to transform raw genetic instructions into precise, functional messages. Meet the spliceosome—a sophisticated cellular machinery that acts like a master editor, carefully sculpting messenger RNA (mRNA) into its perfect, mature form. When DNA's genetic blueprint is first transcribed into preliminary mRNA, it's far from ready for action. The spliceosome steps in as a meticulous genetic tailor, skillfully cutting out unnecessary segments called introns and seamlessly stitching together the essential protein-coding regions known as exons. This intricate process, called splicing, ensures that the genetic information is correctly assembled and prepared to guide protein production. Like a precision instrument, the spliceosome navigates through complex molecular landscapes, making split-second decisions that can dramatically influence how genetic information is ultimately expressed. Its remarkable ability to edit and refine genetic messages is crucial for maintaining the accuracy and efficiency of cellular function.