Industrial Resurgence: America's Manufacturing Muscle Flexes While European Factories Falter

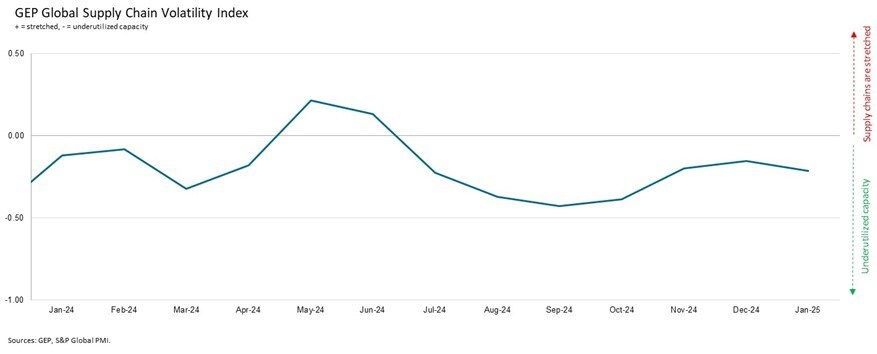

The latest Global Economic Performance (GEP) Index reveals a dynamic landscape of international manufacturing, with the United States emerging as a key driver of global economic momentum. While American industrial sectors continue to show robust growth, Asia demonstrates steady expansion, in stark contrast to Europe's sluggish economic performance. A notable highlight of the recent report is the significant improvement in material supply chains. Despite ongoing challenges with transportation costs, manufacturers are experiencing the lowest material shortage levels in five years. This development signals a potential turning point for global manufacturing resilience and supply chain adaptability. The United States is leading the charge, with manufacturing sectors showing remarkable strength and innovation. Asian markets, particularly in Southeast Asia and China, are maintaining a steady growth trajectory, leveraging their manufacturing capabilities and technological advancements. In contrast, European manufacturing remains tepid, grappling with economic uncertainties, energy challenges, and geopolitical complexities. The region's industrial sectors are struggling to match the dynamism seen in North American and Asian markets. Experts suggest that the current manufacturing trends reflect a broader shift in global economic strategies, with companies increasingly focusing on supply chain diversification, technological integration, and operational efficiency.