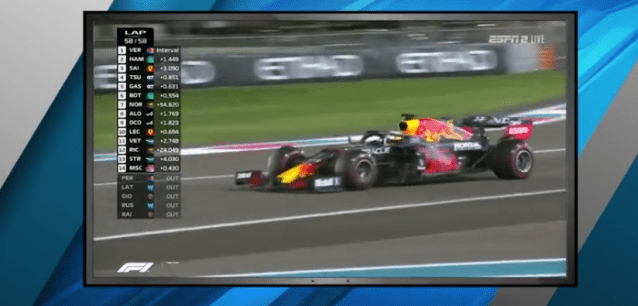

Racing Revolution: Formula 1 Team Eyes Charlotte as New High-Tech Manufacturing Hub

Concord Poised to Become a Powerhouse in Formula 1 Racing The motorsports landscape could be on the brink of a transformative moment as General Motors sets its sights on Concord for a groundbreaking venture. The automotive giant is exploring plans to establish a cutting-edge engine manufacturing facility that could potentially revolutionize the Formula 1 racing world. This strategic move signals GM's ambitious entry into the high-stakes, high-performance realm of international motorsport. By choosing Concord as the potential site for their state-of-the-art facility, the company is not just investing in infrastructure, but positioning the city as a potential epicenter of racing technology and innovation. The proposed facility represents more than just a manufacturing site; it's a testament to Concord's growing reputation as a hub for advanced automotive engineering and technological development. As the project takes shape, local leaders and racing enthusiasts are watching with anticipation, recognizing the potential economic and technological benefits this development could bring to the region.