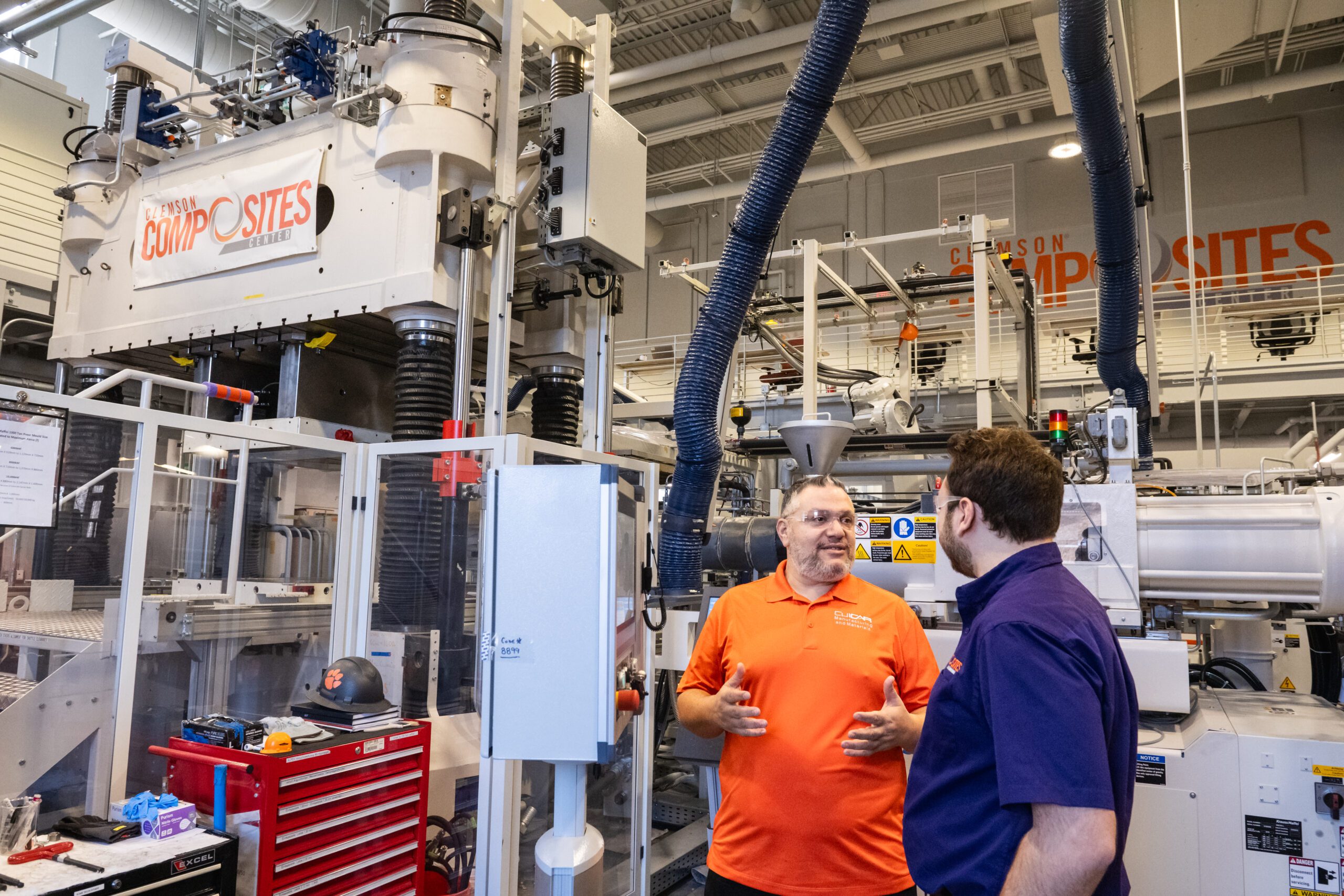

Pharma Powerhouse Meets Academia: Ritedose and Newberry College Unveil Groundbreaking Manufacturing Pathway

Addressing the Talent Shortage: Ritedose Corporation Pioneers Workforce Development in South Carolina's Life Sciences Industry In a strategic move to tackle the escalating demand for skilled professionals, The Ritedose Corporation has launched an innovative partnership aimed at bridging the talent gap in South Carolina's thriving life sciences sector. Recognizing the critical need for trained workforce development, the company is taking proactive steps to cultivate a robust pipeline of qualified professionals. The collaboration represents a forward-thinking approach to addressing workforce challenges, demonstrating Ritedose's commitment to not just meeting current industry needs, but also investing in the future of the life sciences ecosystem. By creating targeted training programs and educational initiatives, the company is positioning itself as a leader in talent cultivation and regional economic growth. This strategic initiative underscores the importance of public-private partnerships in developing a skilled workforce capable of driving innovation and maintaining South Carolina's competitive edge in the life sciences industry. Ritedose Corporation's commitment signals a promising path toward sustainable professional development and economic advancement.