Beyond Virtual Worlds: How the Metaverse Could Revolutionize Manufacturing

The Future of Manufacturing: How AR and Digital Twins Are Transforming Human Potential

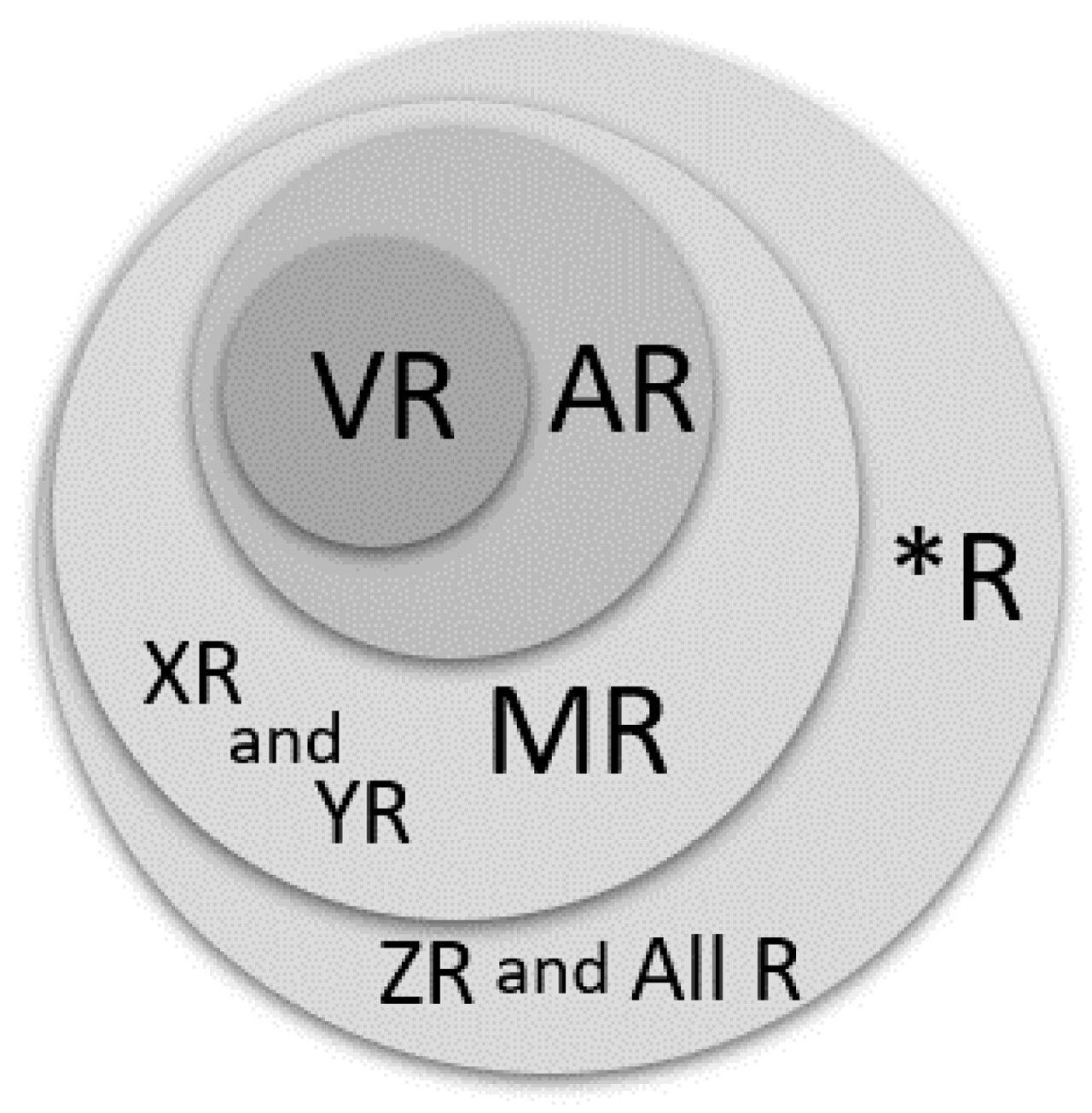

In an era of rapid technological advancement, augmented reality (AR) and digital twin technologies are revolutionizing the manufacturing landscape, dramatically reshaping the role of human workers. Far from replacing employees, these cutting-edge innovations are empowering workers by creating more intelligent, interactive, and collaborative work environments.

Digital twins and AR are bridging the gap between human expertise and technological precision, enabling workers to interact with complex systems in ways never before possible. By overlaying real-time digital information onto physical workspaces, these technologies provide workers with enhanced insights, immediate guidance, and unprecedented problem-solving capabilities.

Imagine technicians wearing AR glasses that instantly display maintenance instructions, highlight potential equipment issues, or provide step-by-step repair guidance. Digital twins allow workers to simulate and optimize processes before implementation, reducing errors and increasing efficiency. This symbiotic relationship between human creativity and technological intelligence is redefining manufacturing's future.

Rather than diminishing human value, these technologies are elevating the workforce's strategic importance. Workers are now becoming high-skilled interpreters and managers of sophisticated technological systems, transforming from manual laborers to innovative problem-solvers and strategic thinkers.

The integration of AR and digital twins isn't just a technological upgrade—it's a human-centric revolution that places skilled workers at the heart of manufacturing's next transformative era.